Efficiency Refined: CTM FlexSine & HighSine Lead the Way for High Frequency Motor Applications

CTM Magnetics air & liquid cooled solutions are changing the way HVAC/Chiller manufacturers design their power systems. Leveraging decades of industry experience along with patented inductor and liquid cooled technology, CTM products provide unrivaled capabilities and benefits all at a lower cost.

CTM solutions provide unparalleled benefits that include higher efficiency, higher frequency/speed capability, reduced noise, and higher power density. While most magnetics suppliers try to solve high frequency by oversizing and derating their equipment, CTM Magnetics solves high frequency harmonics with patented high frequency materials. No derate, higher efficiency, smaller footprint, lower cost.

Optimize your system today with CTM Magnetics solutions.

How we help the HVAC & chillers industry

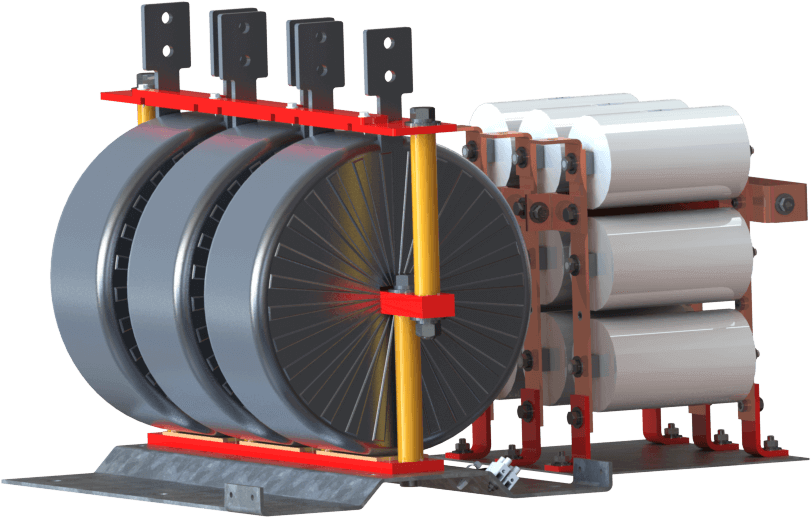

Higher Efficiency

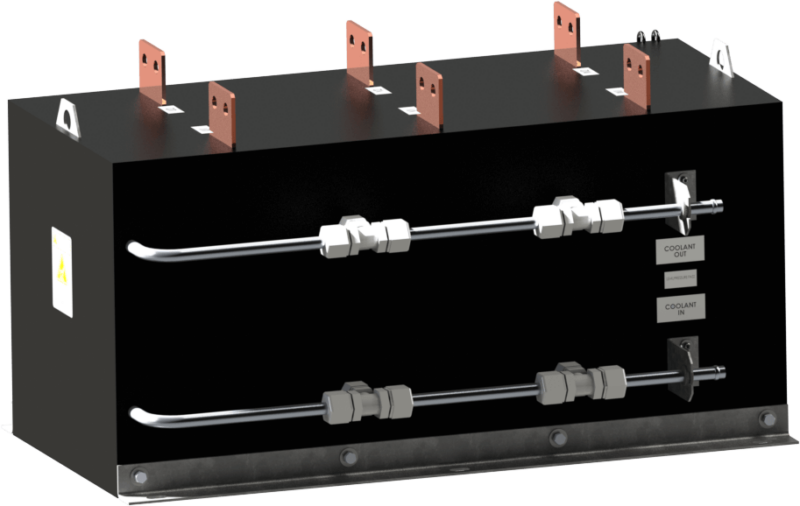

CTM proprietary inductor technology enables higher efficiency even at higher frequencies. Highly efficient materials coupled with state-of-the-art cooling systems result in unparalleled performance.

Higher Frequency

CTM proprietary inductor technology enables the use of higher frequency/speed induction and permanent magnet motors. The use of highly efficient materials allows for greater frequency capability without requiring a costly derate.

Power Density

CTM proprietary inductor technology coupled with state-of-the-art cooling systems result in the highest power density solution on the market.

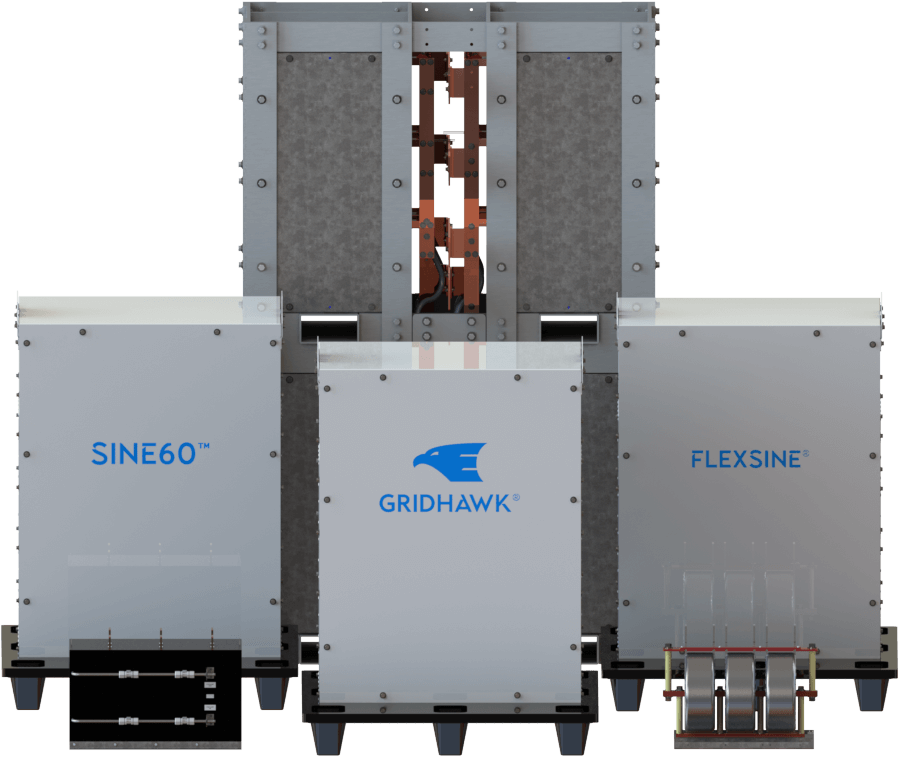

Products that are the perfect fit for the HVAC & Chillers industry

-

Harmonic Filters

Harmonic Filters

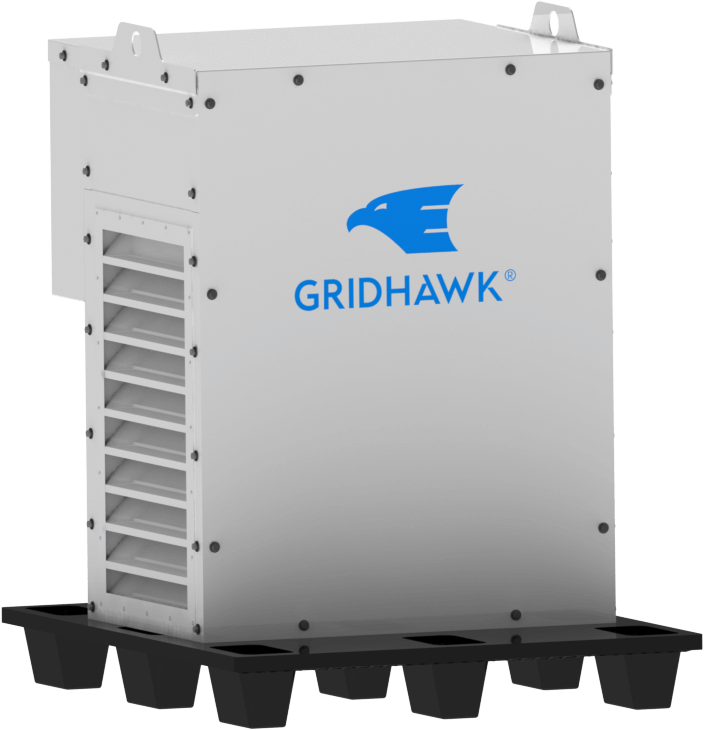

GridHawk® Passive Harmonic Filters (50/60 Hz)

The optimal solution for 60 Hz grid protection and IEEE-519 compliance.

-

Sine Wave Filters

Sine Wave Filters

Highsine™ (240 - 500 Hz)

The optimal solution for high frequency motor protection.

-

Reactors

Reactors

React 60

The optimal reactor solution for 60 Hz VFD applications.

We are here to work with you every step of the way.